Understanding the Problem: Condensation and Rust Formation

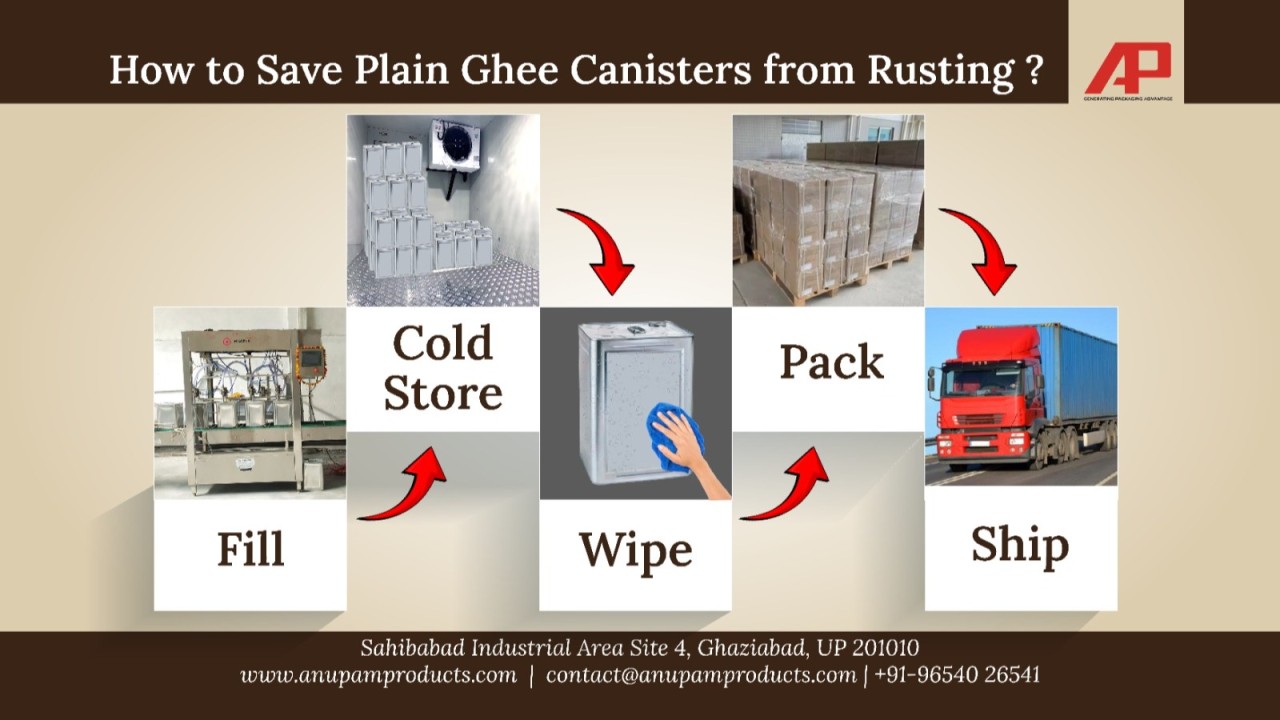

Ghee canisters are often stored in cold environments to preserve the quality of the ghee. When these cold canisters are removed from cold storage, they come into contact with warmer, humid air. This interaction causes condensation—the process where water vapor in the air turns into liquid droplets on the cold surface of the canister.

If these moisture droplets are not promptly addressed, they can lead to rust formation. Rust is not only unsightly but can also compromise the integrity of the canisters and lead to potential contamination of the ghee. Furthermore, rust can negatively impact the brand’s reputation and result in rejection by end users.

Immediate Measures to Prevent Rust

1. Wipe Canisters Immediately

As soon as the canisters are removed from cold storage, they should be wiped down with a clean, dry cloth. This helps remove any moisture that has formed due to condensation. Immediate action is crucial as the longer the moisture stays, the greater the risk of rust.

2. Use Automated Cleaning Systems

For larger operations, consider investing in automated cleaning systems. Conveyor belts equipped with clothes or air blowers can efficiently clean canisters as they move through the packaging line. This not only ensures that all canisters are uniformly cleaned but also speeds up the process.

3. Implement Routine Inspections

Regularly inspect the canisters for any signs of moisture accumulation. Implement a routine check to ensure that your wiping or cleaning systems are functioning effectively and that no canisters are missed.

4. Proper Storage of Tin Containers

To ensure the longevity and quality of tin containers, they should be stored on plastic pallets rather than directly on the floor. This practice helps to prevent moisture damage and contamination. Additionally, it is important to maintain a gap between the containers and the surrounding walls. This spacing facilitates proper air circulation and minimizes the risk of mold or rust formation, ultimately protecting the integrity of the tin and its contents.

Dealing with Existing Rust

If rust is already present on the canisters, it’s important to address it promptly to prevent further damage and maintain product quality:

1. Use Appropriate Cleaning Agents:

Identify and use a cleaning agent specifically designed for removing rust. There are various rust removers available that can help dissolve the rust without damaging the canister. Always follow the manufacturer’s instructions for safe and effective use.

2. Thorough Cleaning:

After applying the rust remover, scrub the affected areas gently to remove the rust. Rinse the canisters thoroughly to remove any residue from the cleaning agent. Ensure the canisters are completely dry before refilling or storing them again.

3. Preventive Coatings:

After cleaning, consider applying a protective coating to the canisters to prevent future rusting. This can provide an extra layer of defense against moisture and environmental factors.

Best Practices for Long-Term Prevention

1. Optimize Storage Conditions:

Ensure that the cold storage area is well-maintained with controlled temperature and humidity levels. Reducing the temperature difference between the storage environment and the surrounding air can help minimize condensation.

2. Regular Maintenance:

Keep cleaning equipment and processes up to date. Regular maintenance of cleaning systems ensures they operate efficiently and effectively.

3. Employee Training:

Train employees on the importance of rust prevention and proper handling procedures. A well-informed team is crucial in maintaining high standards and preventing rust-related issues.

Gireesh Sharma

Director, Manufacturing Industry

Conclusion

Rusting can pose significant challenges in the storage and handling of ghee canisters, impacting both product quality and brand reputation. By implementing immediate cleaning measures, investing in automated systems, and addressing any existing rust promptly, you can safeguard your canisters from rust and maintain the integrity of your product. Regular inspections, optimal storage conditions, and employee training will further enhance your rust prevention strategy, ensuring that your ghee remains fresh and your brand retains its esteemed reputation.