Opening another lot to continue production becomes necessary, but the precious two production hours are lost, impacting your monthly production data. If this recurs, the embarrassment at the monthly management meeting becomes inevitable.

Though this narrative may seem dramatic, it’s not uncommon for a filling line manager. Incorrect or poor-quality Tin Cans lead to significant production losses in industries such as paints, adhesives, edible oil, foodstuff, and gift packaging.

In Tin Can manufacturing, when production peaks, thousands of brands, types, and sizes are produced and shipped every hour. A slight oversight by the quality, packaging, or store department can lead to a chaotic situation. What’s the solution?

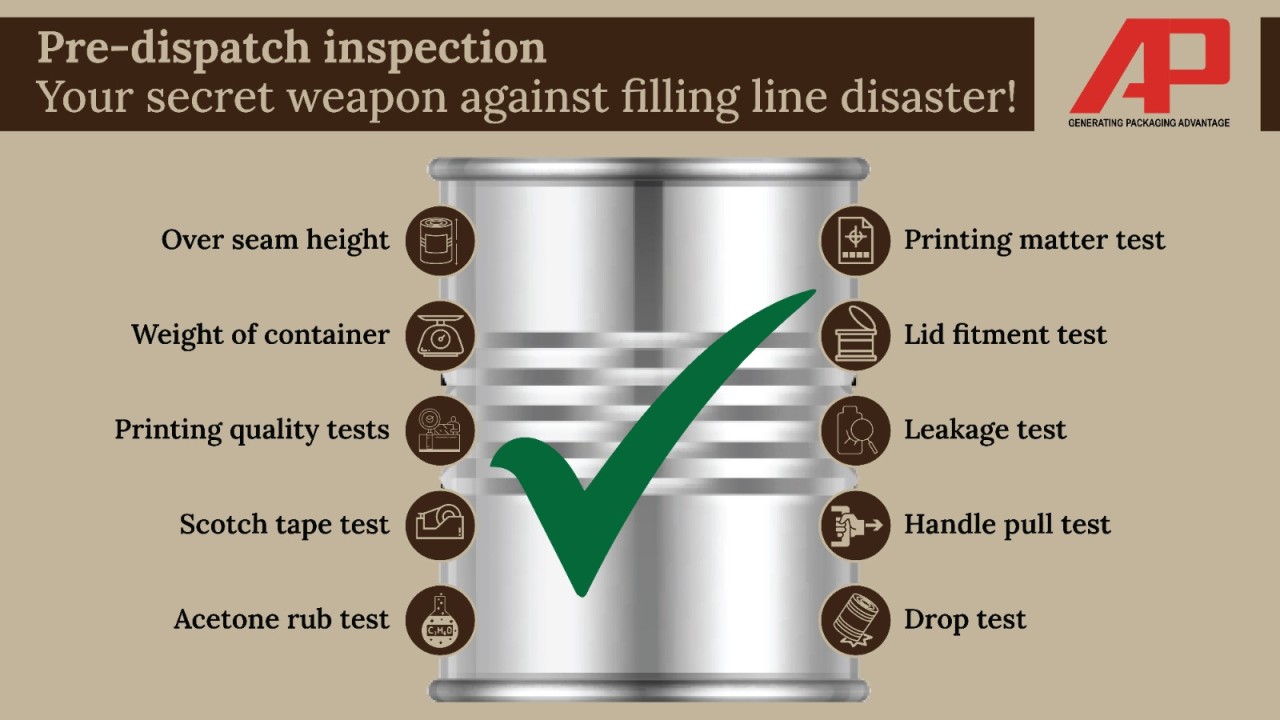

Anupam Products’ Pre-Despatch Inspection

At Anupam Products, we strive to spare Filling Line Managers and Purchase Managers from such embarrassments. Among our many manufacturing best practices, “Pre-despatch Inspection” ensures a 100% Correct Delivery to our customers.

In a pre-despatch inspection, the goods undergo over 10 tests before the delivery trucks leave our premises. Let’s explore these tests briefly:

- Tin Can Height – The purpose of this test is to measure the height of the Tin Container so it fits in the filling line without any obstructions.

- Weight of Container – We select a set of Tin Cans and check their gross weight for any deviation, allowing a 5% play.

- Scotch Tape Test – A 2-inch length of Scotch tape is applied to the Tin Can, pulled, and checked for print damage.

- Acetone Rub Test – A cotton swab dipped in Acetone is rubbed on the Tin Can to check for print or coating damage.

- Printing Matter Test – Samples are compared word by word and color by color with the approved client sample.

- Lid Fitment Test – Samples are tried with multiple lids to ensure proper fit with sufficient pressure.

- Leakage Test – Cans are filled and tested for leaks, including pressurized air tests.

- Handle Pull Test – If a Tin Can has a handle, it is pulled to ensure it stays intact.

- Drop Test – Filled cans are dropped multiple times from a specified height to check for deformities or lid openings.

The Quality Control team at Anupam Products ensures that a sufficient number of samples undergo random testing before dispatching goods to customers’ filling lines.

This rigorous testing establishes Anupam Products as a trusted partner for Tin Can packaging with consumer brands.

Gireesh Sharma

Director, Manufacturing Industry

Under pressure to meet production numbers, you might feel like you’ve never ordered from this supplier, trailing the frustrations of the purchase manager.